Supply Shortages in the HVAC Industry Expected to Further Drive-Up Prices

Irvine, California, October 4, 2021 – The supply shortages of 2021 have led to price spikes and longer delivery times on key HVAC supplies. Raiven, a leading purchasing platform for contractors, shares research on the causes and best practices for HVAC contractors.

What caused the HVAC supply shortages and price spikes?

The last 18 months have been hard for HVAC contractors, even without referring to pandemic-related challenges. The United States just went through the hottest summer ever recorded for the Pacific Northwest and the Southwest, which put further strain on the already-struggling market where manufacturing is currently unable to keep up with spiking demand.

According to Raiven HVAC supply chain research, manufacturing and shipping bottlenecks have the highest effect on HVAC prices. Unfortunately, 7% of all manufacturing labor was lost due to COVID-19, and the industry has been slow to recover. In addition, maritime shipping and air freight were cut as much as 25% during the peak of the pandemic, creating bottlenecks that still haven’t stabilized. Thus, the majority (90%) of original equipment manufacturers believe that HVAC is experiencing a shortage – and that it’s likely to get worse later in the year.

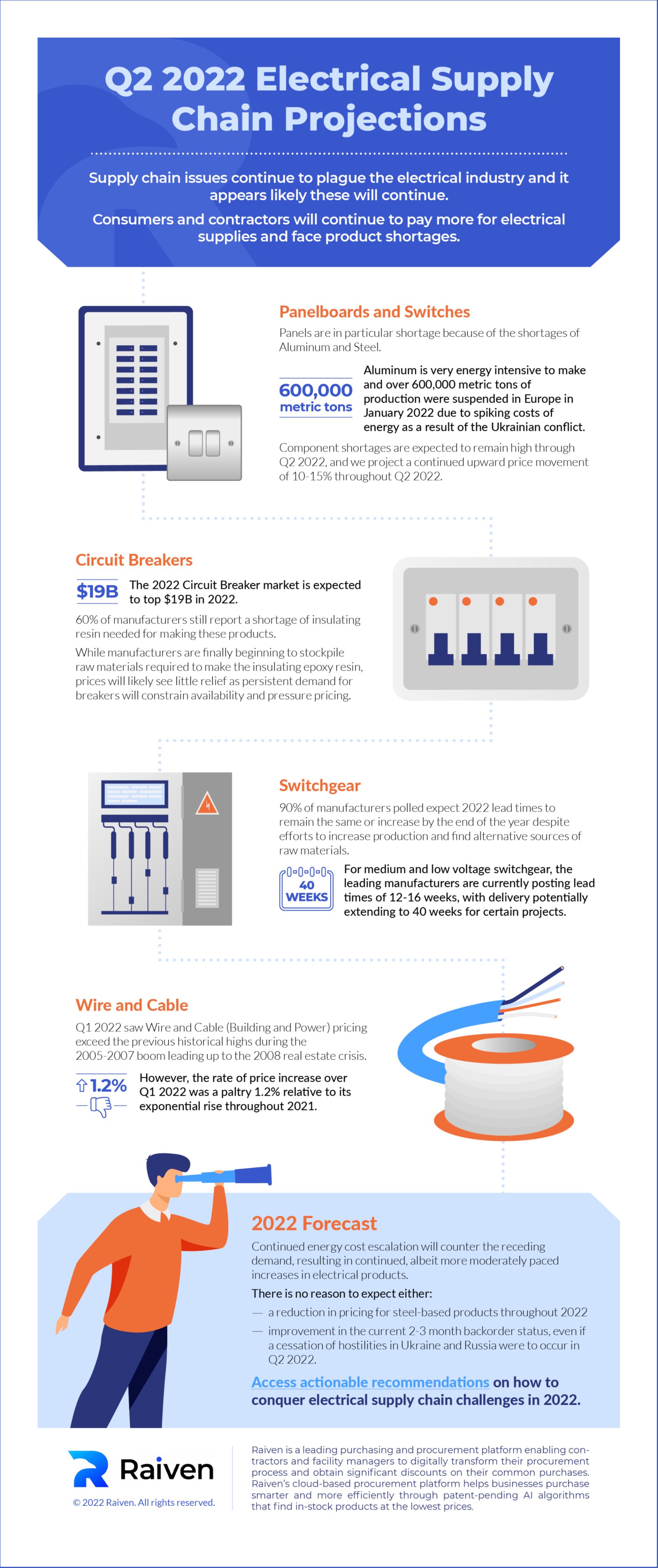

This situation is already made worse by severe price spikes for raw materials – copper, steel, aluminum, and plastic have all spiked due to shortages. Copper and steel both doubled in price between 2020 and 2021, echoing increased prices on most HVAC supplies.

Will HVAC prices continue to rise?

Raiven found that major manufacturers all announced price increases, ranging from a 5% increase to 9%. Specialized equipment that involves semiconductors is likely to see 10-30% increases due to unique problems in the industry. Air conditioner manufacturers are also facing a storm of demand and labor challenges. Distributor lead times are at an all-time high since 1987.

Some shortages such as copper and steel are expected to persist well into 2023. Periods of relief should follow up with steady price increases, to the point where certain HVAC supplies common today will become less available for the average contractor.

How HVAC contractors can secure their supply chains

Raiven offers four key practices for HVAC contractors to succeed in the changing market:

- Strategic purchasing: Join a purchasing program that aggregates the spend of all its clients, so you receive higher priority with your orders, better pricing, and more efficient ways of purchasing.

- Leverage technology: Instead of manually searching multiple supplier websites for product availability and the lowest price, acquire software tools that do this for you automatically to save you time and money.

- Diversification: Certain distributors are slower to respond to price changes than others. It may take months for some companies to announce a price increase. So, taking advantage of those lagging distributors is an opportunity to stock up on crucial supplies.

- Communication: Work directly with suppliers to understand lead times and price trends. Building long-term relationships and driving spend to trusted contacts will help ease the effect of shortages.

“Brett Knox, CEO of Raiven, explains, “The HVAC industry is experiencing a perfect storm due to far-ranging supply chain issues that aren’t going away in the next 6-9 months. HVAC contractors should utilize AI algorithms like Raiven’s to quickly find where HVAC supplies are in-stock and at the best value – saving them time and money while helping to delight their customers.”

About Raiven

Raiven is a leading purchasing platform, saving contractors and facility managers 7-25% on their everyday purchases. Raiven’s cloud-based procurement platform helps businesses source and purchase smarter and more efficiently through patent-pending AI algorithms and a purchasing program that delivers significant discounts from industry-leading suppliers. Read more at Raiven.com.

Contact

Jeff Golden

(503) 709-0286

jeff.golden@raiven.com